ARTWORK GUIDE

Design is our job

The design of your product is very important to us and your, therefore we’ve created a guideline for your artwork. The maximum amount of single colors that we can print is 10 (in flexo or rotogravure printing), this includes white and mat finish. The paper like varnish is excluded. Please make sure to follow all the recommendations on this artwork guide. It is the only way to ensure the best result for your products.

Software/Format:

- Adobe Illustrator (Preferred) or Photoshop: AI or EPS formats.

All text and fonts converted to outlines.

Images:

-

All Photoshop image files should be linked and attached. Never flatten the layers and do not change the directory.

-

The resolution of photographic image files must be on scale 1:1 and no less than 300 dpi

-

Do not use scan pictures for images.

-

Make sure images is saved at high resolution in CMYK color mode not RGB mode.

If you use single colors, please use Pantone colors as a reference – when using CMYK color, before the production you will receive a proof to check the colors. The proof is made on paper that imitatesthe plastic.

Fonts:

-

Create all fonts in artwork in outlines, curves or paths (vectorized)

-

Please include all screen and printer fonts (Suitcase and Postscript fonts)

-

Always double check the spelling, content and layout.

Barcodes:

-

All barcodes (UPC codes) should be scaled at 100% or larger.

-

Make sure background and bar colors must be contrasting to allow proper scanning.

Artwork File Submission:

Please make sure to compress (zip) your files, prior to submission. To prevent file corruption when compressed, please do not use a tool operating under OS such as Stuffit but a PC tool such as WinRar or WinZip. You can submit your artwork files (one file for each artwork) on the following medias:

-

E-mail (file size 5MB or less only)

-

-

FTP (If you want to submit your artwork via our FTP server, please contact us)

-

CD or DVD

All files must be accompanied with a hard copy proof or low-resolution PDF for reference.

Information to be considered when creating graphics:

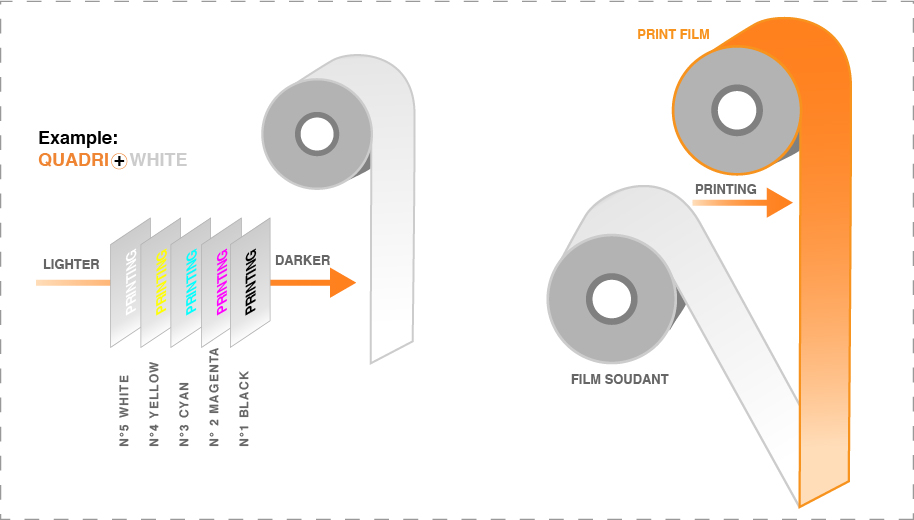

- Optical properties of the film used for the pouch: a transparent film needs a solid white to enhance the printing. (Without this plain white, the colours with lower opacity would become translucent.) A metallized film requires a plain colour as well to avoid alteration of the colours. (Otherwise the yellow would become golden lustre.). Unless a full white is needed, the position of the white and the blanks should be indicated when forwarding the files.

- Content of the pouch: a printing on a transparent film will never be opaque even with several full white coverings – this can be solved to change the material and to use a white colour in the batch of the plastic.

- Register tolerances between single-color stations on the printing press:

- Flexo 0,1 mm

- Rotogravure 0,15 mm

(You shouldn’t bear in mind this information to make fall-backs; we have to anticipate as we have to compensate anamorphosis. However, you should avoid some graphic practices such as fine text openings in the CMYK, fine outlines or frames in a color made from CMYK, …).

- The pouch making requires that sealing jaws avoid contact with the printing inks (exterior printing). The slitting of the pouches will cause a shift of 3 mm in the machine running direction and 1 mm across the film (transverse direction). We recommend the edge of 3 mm should be either unprinted or in a solid colour or in a symmetric printing pattern between the left and the right of the pouch both front and back side as to have a fall-back area. When the pouch is featuring easy open tear notches, they should be arranged at 20 mm from the top of the pouch. When the pouch is featuring a reclosable zipper, it should be arranged at 30 mm from the top of the pouch.

- Characteristics of the used film for the pouch making: a multilayer film will receive a so-called reverse printing between two layers on the underside of a transparent film enabling the correct image to appear when viewed from the front. A single layer film will receive an exterior printing on top of the film. When using a single layer film, the printing inks shouldn’t be in contact with the sealing devices of the packaging machines. Therefore the areas which are to be sealed will usually be exempt from Corona treatment (When creating the graphist should consider the areas which are indicated on the drawing provided by the packaging machine manufacturer).

- Packaging process: Packaging occurs as flat film, tubular film or pouches/bags. The printing of these products should match the customer’s filling lines or our converting machines.

From the customer’s view … A film or a tubular film will receive a register mark which will normally be located on the extreme left or right of the film and in an area without printing. This color square enables the machine by contrast measuring to define the motion which corresponds to the repeat length of the packaging. (The size of the photocell mark, the position and the blank area should be defined by the packaging machine manufacturer). The printing on a film should meet a layout scheme which is normally arranged from left to right and back1/front/back2 (Please refer to the instructions provided by the packaging machine manufacturer). In the case of preformed pouches, regardless of the closure system, (e.g. sealing, zipper, …), the involved area should be defined because of the surface distortion risk depending on the closure system (Information’s to be obtained from the machine operator).